DATE

Interstellar’s ZERO Rocket Turbopump Completes Power Pack Test

CATEGORY

TAG

Hokkaido, Japan – Interstellar Technologies Inc. (“Interstellar”), a leading space infrastructure company dedicated to addressing global challenges through space transportation and utilization, has successfully conducted the Power Pack Test of the turbopump for the COSMOS engine of the orbital class launch vehicle ZERO at the IHI Aerospace Aioi Test Site (Aioi City, Hyogo Prefecture). This marks the completion of the subscale turbopump model development. As a result, Interstellar is now the first venture organization, apart from Japanese flagship rocket-related enterprises, to possess proprietary turbopump technology, which enables the development of one of the most challenging components in rocket engineering.

Compact, Lightweight, and Low-Cost Turbopump System by a Seasoned Team

The turbopump is the “heart” that delivers fuel and oxidizer to the combustion chamber, and for ZERO, Interstellar has adopted a a single-shaft design that integrates both the fuel and oxidizer pumps. While this design is more technically demanding compared to separating the pumps, it enables overall reduction in engine system size, weight, and part count, leading to cost savings. The turbopump used in the test is a subscale model (42 cm in length, 19 cm in diameter) made from heat-resistant nickel alloy, with some parts made of titanium and aluminum alloys.

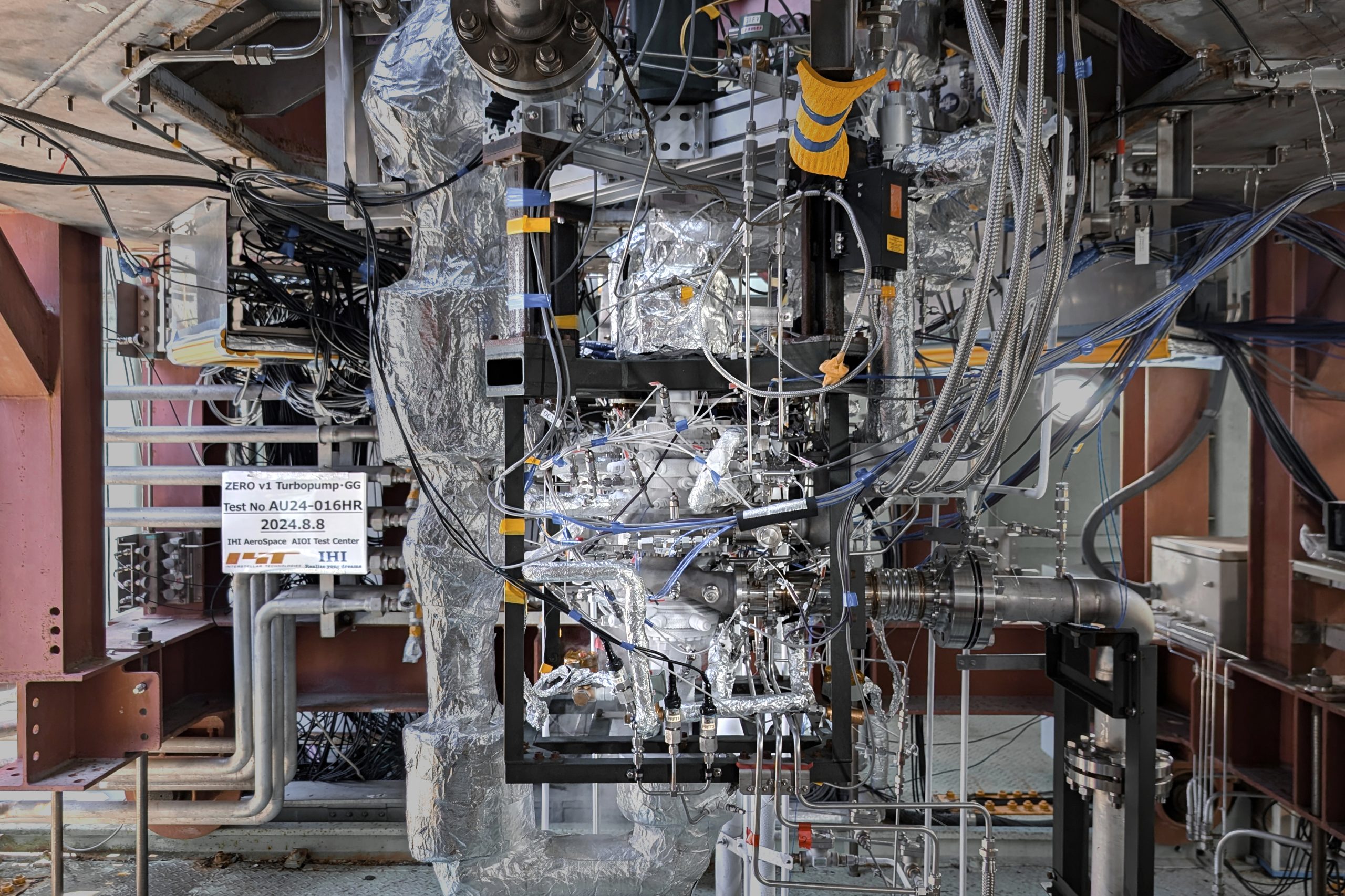

The Power Pack Test, which serving as the final phase of turbopump development, verifies the performance of the entire system, including the gas generator (GG) and heat exchanger (HEX) that provide the driving gas for the turbine.This test confirms the turbopump’s successful operation at the target RPM.

The turbopump team at Interstellar consists of individuals with experience in turbopump development for Japanese flagship rockets as well as expertise in rocket system design.

In parallel with the test, Interstellar has already finalized the design of a flight development model, and is currently in the assembly process, with plans to test this model during this winter. By maintaining in-house control over core technologies like the turbopump, Interstellar is developing cost-competitive rockets, with the goal of making space accessible to everyone.

ZERO Engine Power Pack Test Summary

Test Name: Power Pack Test for Turbopump in ZERO Rocket Engine

Test Objective: To verify performance of the engine subsystems, including the turbopump, gas generator and heat exchanger

Test Period: July to August 2024 (six tests in total)

Location: IHI Aerospace Aioi Test Site (Aioi City, Hyogo Prefecture)

Test Result: Achieved the target RPM, confirming the viability of the engine system

Incorporating Japanese Expertise in Development

The development of the turbopump for the ZERO engine began in 2019 as part of a joint research collaboration with the National University Corporation Muroran Institute of Technology (Muroran City, Hokkaido), leveraging their extensive experience and achievements in the development of engines for Japan’s flagship rockets. In September 2021, EBARA Corporation (Ota-ku, Tokyo), the primary Japanese pump manufacturer, entered into the collaboration, signaling the onset of a joint endeavor in research and development involving all three entities.

Subsequent tests were carried out at the IHI Aerospace Aioi Test Site, supported by IHI Aerospace (based in Tomioka City, Gunma Prefecture), renowned for their experience in rocket engine and turbopump testing (*1).

Integrating domestic expertise throughout the design, manufacturing, and testing phases, particularly given the challenges of the turbopump, has been paramount.

*1 Funding support for some turbopump research and development was received from the Ministry of Economy, Trade and Industry’s Strategic Innovation Program for Advanced Technologies (JPJ005698)

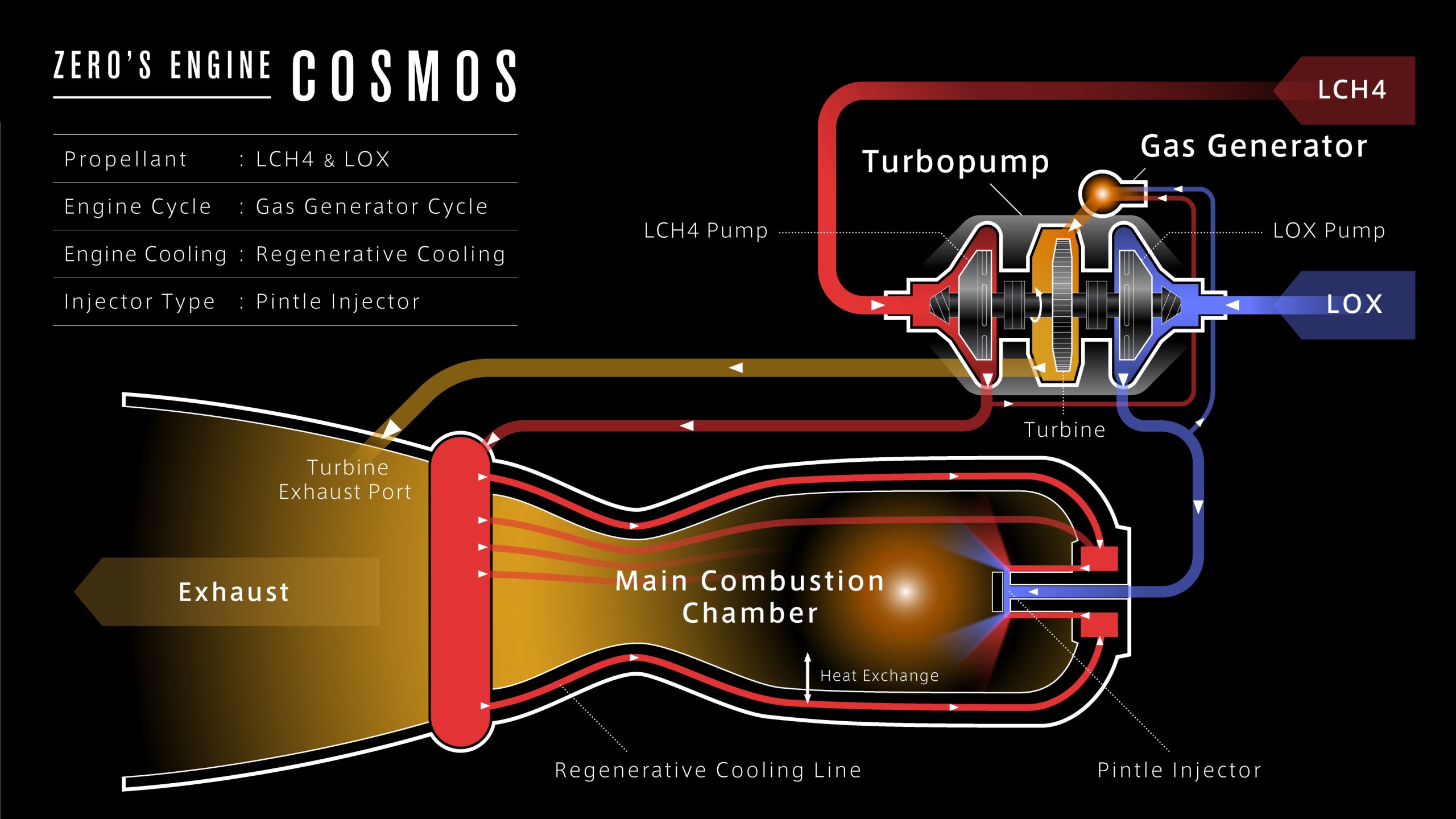

Adoption of Gas Generator Cycle and Regenerative Cooling System

Interstellar has, for the first time, incorporated the gas generator cycle in the ZERO engine, where the power is generated by the gas produced in the gas generator to drive the turbopump and high-speed turbine, which then supplies the propellants at high pressure to the combustion chamber. The regenerative cooling system, where fuel is also used to cool the combustion chamber, has also been implemented. Interstellar has already conducted individual tests on the gas generator, combustion chamber, and turbopump, and plans to proceed with the integrated engine test in the future. The engine of the ZERO is named ‘COSMOS.’ This name was selected by the development team because ‘cosmos’ is the flower of Taiki, and the injection pattern of the pintle-type injector, which is a distinctive feature of this engine, resembles the petals of the cosmos flower.

Competitive Pricing and Dedicated Launch Capability

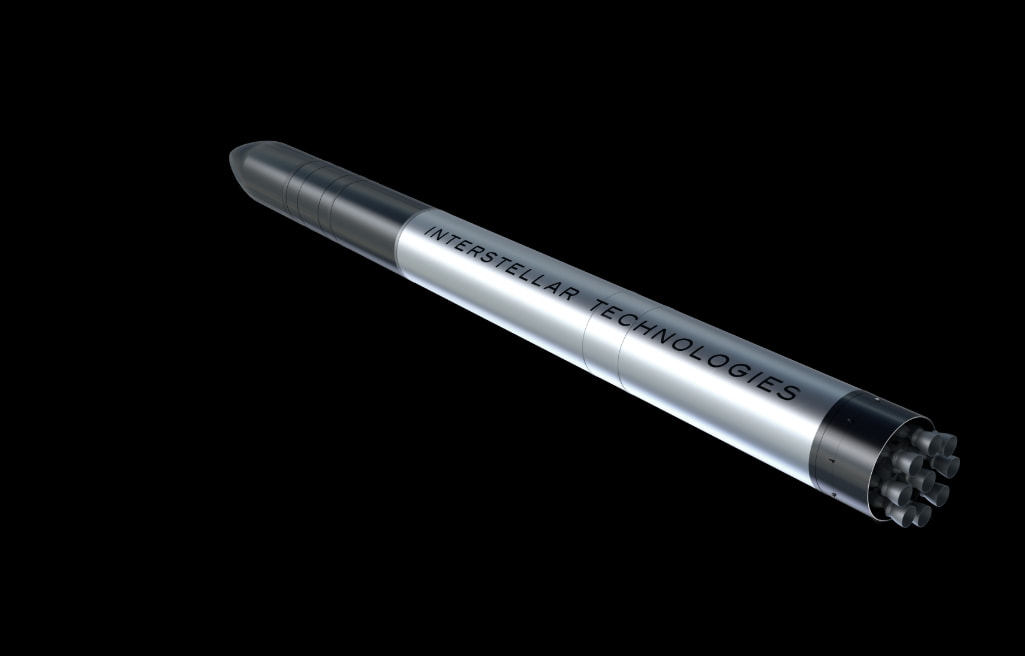

ZERO is an orbital class launch vehicle designed to target the growing market for small-sized satellites in recent years. Building on the knowledge gained from the successful launch of the private suborbital launch vehicle MOMO, the first of its kind in Japan’s private sector, Interstellar is progressing toward the first launch of ZERO.

ZERO’s space transportation service distinguishes itself with competitive pricing—at less than 800 million JPY per launch (in mass production)—made possible through an integrated development and manufacturing process. Another key strength is its flexibility to provide customized launches tailored to the rising needs of satellite companies. For satellite companies in Japan, Asia, and Oceania, proximity to the launch site ensures convenience, reducing launch-related time and costs and enhancing overall value.

ZERO’s Capacity Boost: To establish Asia-Oceania Market Presence

With an eye on recent trends and the demand both locally and globally, ZERO is enhancing its capacity to launch satellites of up to 800 kilograms into Low Earth Orbit (LEO). This strategic enhancement contributes to the establishment of an independent domestic space transportation service and positions Interstellar to secure a firm presence in the Asia-Oceania and European markets.

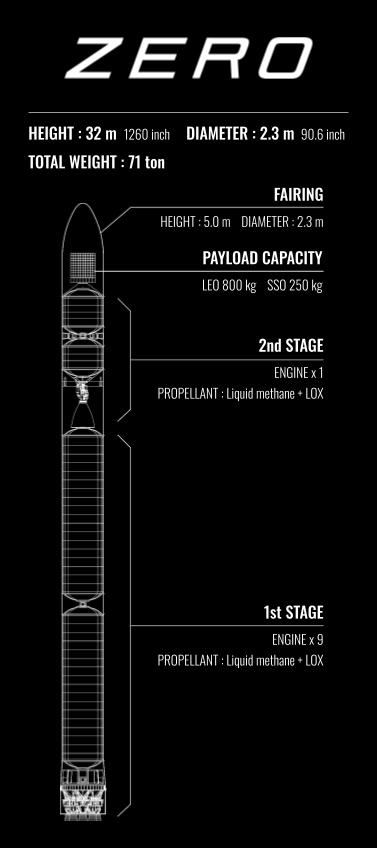

ZERO: Specifications

Height: 32 m

Diameter: 2.3 m

Wet mas: Weight: 71 ton

Propellant: Liquid Methane (Biomethane) Oxidizer: Liquid Oxygen

Number of Engines: 1st Stage: 9, 2nd Stage: 1

Payload Capacity: LEO 800 kg / SSO 250 kg

Press Release | 20240823_Intersteller’s ZERO Rocket Turbopump Completes Power Pack Test